Professional Protruding Solar Road Studs Related Knowledge Is Here

Buried Solar Road Studs can be divided into buried type and protruding type according to different installation positions. The former is generally used in the center line, and the latter is generally used in the edge line. This is because the Solar Road Studs installed on the center line require particularly high pressure resistance. In order to solve this problem, the Solar Road Studs had to be buried in the ground, and only about 5 mm of the ground was exposed. The Solar Road Studs used on the edge line does not require particularly high pressure resistance, and it can still work effectively when it protrudes from the ground. Solar Road Studs can be divided into capacitive type and battery type according to different energy storage components. The service life of the former can reach five to seven years, and the service life of the latter generally ranges from one to three years. Because the buried Solar Road Studs damage the road surface greatly, and the capacitive Solar Road Studs are too costly, so the most commonly used solar Road Studs are raised batteries. The indicators for measuring the performance of a solar road stud are as follows:

Compression resistance: If Road Studs cannot withstand a certain amount of pressure, it will easily break after the car is crushed or impacted, and naturally cannot work normally. Therefore, compression resistance is a basic condition for Road Studs to work normally. But the problem is that Road Studs itself is an electronic product that contains electronic parts. It is indeed not an easy task to make the electronic parts have a higher degree of compressive performance. Therefore, in general, the compressive performance of Solar Road Studs is better than ordinary ones. Road Studs is worse. The current technical requirement of the Ministry of Communications is 10 tons. There are several ways to effectively improve the compression performance of Road Studs: one is to use PC bulletproof materials for the exposed solar panels to enhance the compression resistance of the electronic parts; the other is to use IC control as much as possible to reduce electronic circuits The volume is used to reduce the pressure on the electronic part; the third is to design some stiffeners on the shell to share the pressure on the electronic part.

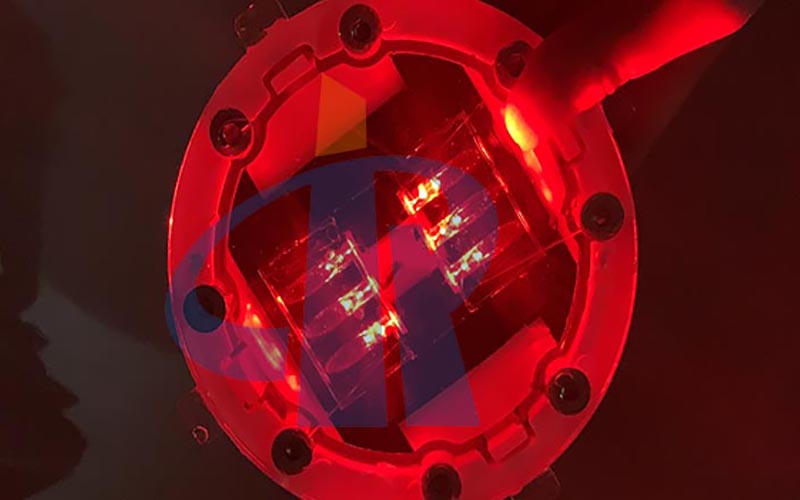

Sealing performance: If the Solar Studs is not completely sealed, it will naturally seep water, which will cause a short circuit in the circuit, and the consequences are catastrophic. Therefore, a qualified Solar Studs must pass the seal. There are several ways to improve the sealing performance of Solar Studs: (1) Separate design. The LED lampshade and the internal circuit board adopt an isolation design. Even if the LED lampshade is broken, the interior of the Solar Studs is still guaranteed not to seep; (2) Strong neutral bonding materials are used to ensure that the solar panel, the LED lampshade and the road stud housing are tightly bonded , There is no gap in the middle.

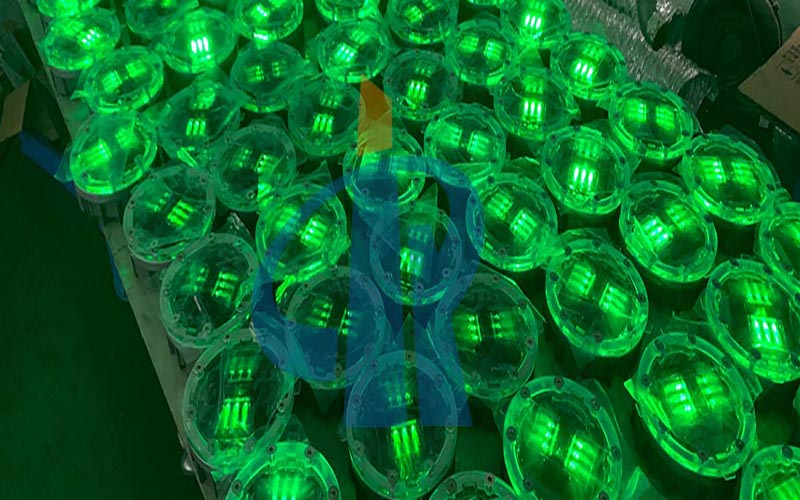

Brightness: Solar Studs actively emit light, clearly delineating the outline of the road; compared to Reflective Studs, its very important feature is its high luminous intensity. This indicator is required by the Ministry of Transportation to be 2,000 MCDs.

Stability Battery life An important factor that determines the life of Solar Studs is the life of the battery. The choice of battery is very important. There are currently two types of batteries on the market that can be used for reference. One is that the battery capacity is reduced to 50% after 500 times of charging and discharging; the other is that after 1000 times of charging and discharging, the battery capacity is reduced to 79%. The battery life must not only be long enough, but also be able to work normally in a larger temperature range. There are chemical substances inside the battery. If the temperature is too high or too low, the battery will not work. The operating temperature range of the Solar Studs battery must meet the requirements of the actual use environment. The requirement of the Ministry of Transport is from -10 degrees to 50 degrees. The actual environment often exceeds this range, which places higher requirements on the battery. The design of electronic circuit boards must follow simple and effective design principles, and do not artificially complicate, because one more circuit will increase the possibility of failure. Electronic components must also be carefully selected, because any problem with any electronic component may paralyze the entire system. Welding must be reliable, because Solar Studs bears the rolling and impact of vehicles every day, and a little looseness of the solder joints will cause the line to loosen and fall off. Therefore, when choosing a welding gun and soldering tin, you must choose high-quality products to ensure that the solder joints are firm and reliable, and can work in a relatively “bad” environment for a long time. Solar Panels Solar panels directly absorb solar energy and convert light energy into electrical energy. It can be said to be the first link in the entire working system of Solar Studs; its working efficiency directly determines the working efficiency of Solar Studs. Nowadays, monocrystalline silicon solar panels are commonly used. This is because the photoelectric conversion rate of monocrystalline silicon solar panels is relatively high, about 14%, which can convert solar energy into electric energy to the greatest extent to ensure the energy for Solar Studs. supply. In addition, the solar panel must be a high-hardness, wear-resistant circuit board. Solar panels have to withstand the crushing and wear of wheels every day. If the strength is not enough, it is easy to grind, which will affect the conversion efficiency of solar panels.

The battery matching performance should be placed for 8 hours under standard test conditions, and the rated capacity of the battery should meet the need for the road stud to emit light for 72 hours; even if the solar illuminance is less than 1000LX, the battery’s rated capacity should meet Road Studs normal after 8 hours of charging The need to glow for 12 hours. This must also be paid special attention. If the battery matching performance is not good, there will be insufficient battery storage power in the rainy weather, causing the solar road stud to fail to emit light. In this way, Road Studs has no practical value and cannot be used at all. This is the limitation of capacitive Road Studs. Placed for 8 hours under standard test conditions, the rated capacity of the capacitor can generally only meet the needs of the road stud for 12-14 hours of normal light emission. Therefore, capacitive Road Studs have very strict requirements for the actual use environment, not only the sunlight must be strong enough , And there can be no continuous rainy weather, otherwise it will be difficult to work normally.